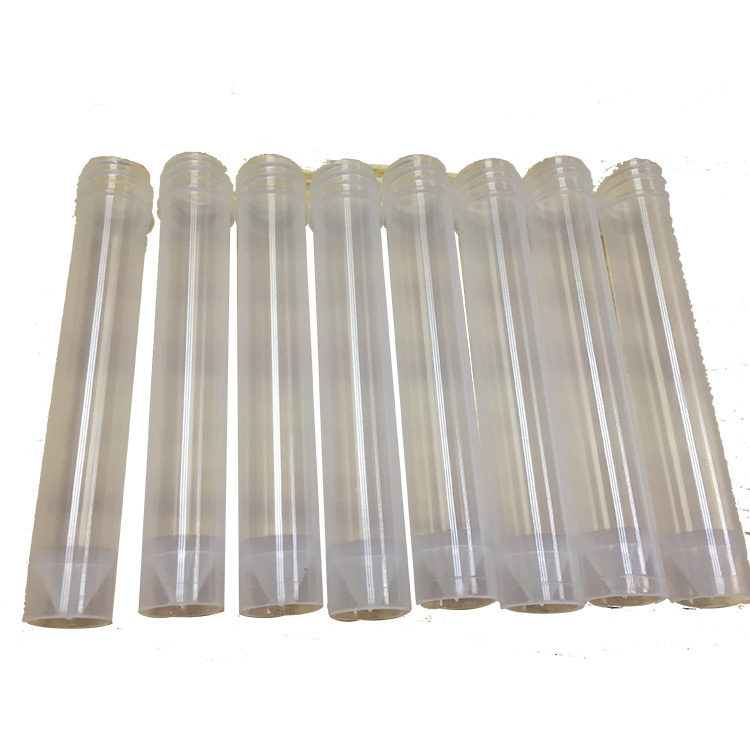

Product Basic Information:

Product Name: Multi Cavity Parts

Model Number: TD18

Brand Name: OEM

Material: PA-6 30%GF

Cav. No. : 2+2+4 cavity

Application: Household

Technology: Mould Injection

Color/Surface finish: Custom Color

Size: According to your drawings

Packaging Details: Poly bag+export carton or according to customers’ requirements

Port: Shenzhen, China

Lead time: 4 weeks

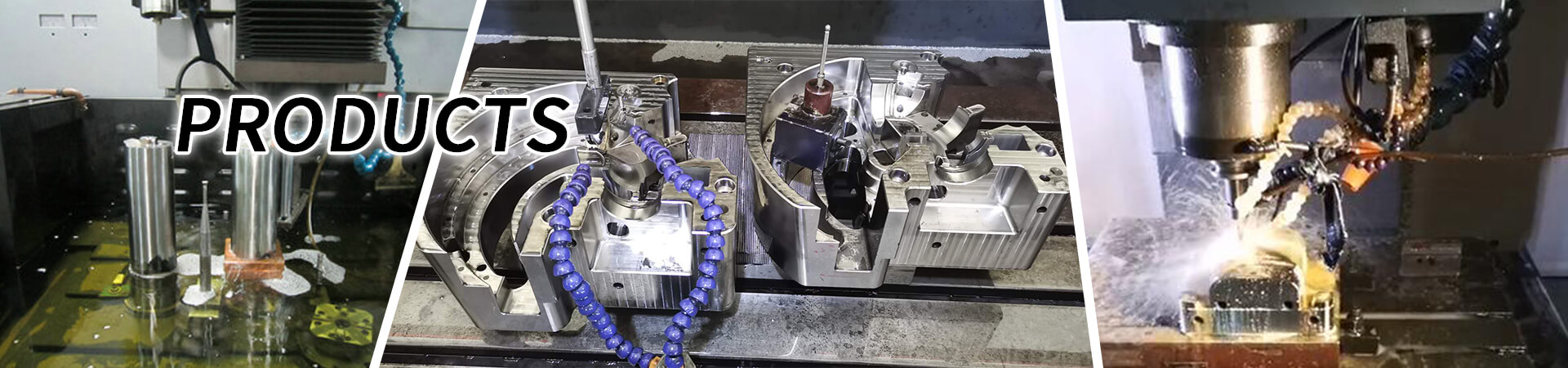

1.Advanced equipments and technicals.

2.TTM adopts lean practices and process optimization including the use of technology to achieve“best costs”.

3.Strict quality management is enforced at all stages.

4.In-house Mould design and manufacturing.

5.Experienced good service on developing designs and quick response.

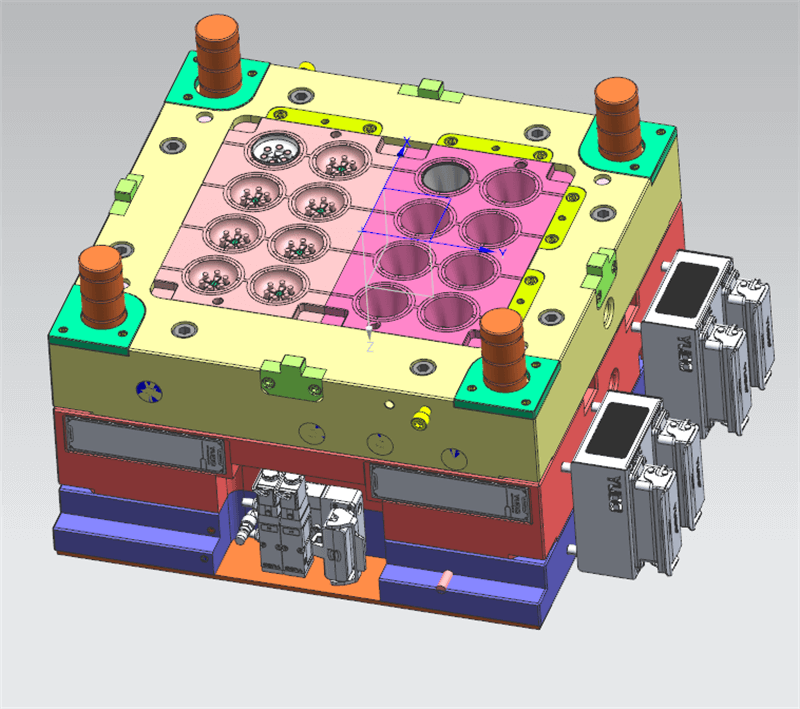

Product Design

Product Feasibility Research & Analysis

Mould Flow Analysis with DFM Report

Product & Mould 2D/3D Design

Designing a great product and mould requires understanding every step of

the development process. Talent Mould has that understanding. In our

designing department, 12 design engineers with rich experience

in product design and mould design are always ready for

your project.

Latest mould design software we are now using:

2D: Auto-CAD 2014, Edrawing, etc

3D: Pro/Engineer, Unigraphics 9.0, Solidworks, Catia, Moldflow 2012, etc

CNC Programming: MasterCAM, Unigraphics 8.0, etc

We can readily receive small and large CAD files in a variety of formats, like:

2D: dwg, dxf, edrw, pdf, etc

3D: step, igs, x_t, prt, Sldprt, etc

We guarantee your idea will be taken step-by-step through the process, from CAD design through production and assembly.

A project engineer will be assigned to follow your order right through the design to sampling and tool shipment. The engineer will act as your representative to make sure the technical and quality standard are fully implemented, and do not worry they speak and understand English very well.

The weekly progress report and online tracking project management ensure the process is running on schedule to avoid rushing in last minute.

Following final design approval and tool manufacture, samples are submitted with a fully detailed inspection report and setting parameter.

To be always able to deliver high quality mould an plastic products to our customers, the highest level of quality assurance is essential for us .

This starts with the contract review over the entire project cycle and ends with the shipping process.

We have therefore implemented a Quality Management System according to ISO 9001:2015 allowing for continuous improvement of our processes.